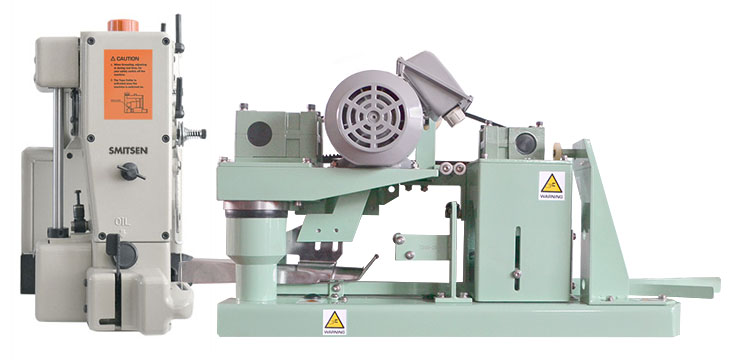

The Smitsen DS-9 series is by far the most diverse series of all high speed sewing heads available on the market. With 2x oil baths in the machine. The most popular is the DS-9C with a speed of up to 2700 RPM and an integrated knife to cut through thread or Crepe Tape. For a double needle, double stitch the DS-9CW closes a diversity of bags. If you need to feed bags by hand, The Smitsen DS-9A with foot pedal is an ideal solution. If you are working in the potato industry or if you are working with net bags, the Smitsen DS-9P is the excellent choice.

The Smitsen DS-9 series is by far the most diverse series of all high speed sewing heads available on the market. With 2x oil baths in the machine. The most popular is the DS-9C with a speed of up to 2700 RPM and an integrated knife to cut through thread or Crepe Tape. For a double needle, double stitch the DS-9CW closes a diversity of bags. If you need to feed bags by hand, The Smitsen DS-9A with foot pedal is an ideal solution. If you are working in the potato industry or if you are working with net bags, the Smitsen DS-9P is the excellent choice.

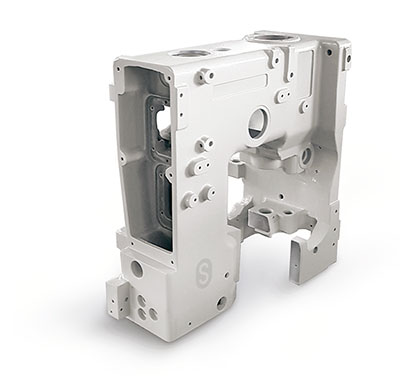

2x Oil Bath

All the Sewing heads from the Smitsen DS-9 series have an upper and a lower oil bath. It does not only make the machine run as fast as it can, it also reduces maintenance and wear of parts to a minimum. If you are working with corrosive materials or products in the food industry, the oil baths protects the machine for hazardous materials and keeping contamination of food to an absolut minimum.

Examples of usage: packing flower, carbon black, charcoal, sugar, fertelizers, potatoes, unions, seeds, and simular products.

Integrated knife

The Smitsen DS-9C and DS-9CW machine models come with an air operated knife that is already preinstalled with the machine. An SMC Air valve and air filter are included with every DS-9C and DS-9CW machine. All you have to do is provide it some air.

2x Oil Bath

All the Sewing heads from the Smitsen DS-9 series have an upper and a lower oil bath. It does not only make the machine run as fast as it can, it also reduces maintenance and wear of parts to a minimum. If you are working with corrosive materials or products in the food industry, the oil baths protects the machine for hazardous materials and keeping contamination of food to an absolut minimum.

Examples of usage: packing flower, carbon black, charcoal, sugar, fertelizers, potatoes, unions, seeds, and simular products.

Integrated knife

The Smitsen DS-9C and DS-9CW machine models come with an air operated knife that is already preinstalled with the machine. An SMC Air valve and air filter are included with every DS-9C and DS-9CW machine. All you have to do is provide it some air.

The Smitsen DS-9C is an excellent Crepe tape machine

The DS-9C is excellent for applying crepe tape. Every DS-9C comes standard with the knife that cuts through the Crepe tape and the thread at the same time. The machine can extended with a Crepe tape binder or the CM4900-3 Crepe Tape infeeder.

Features on DS-9 series sewing head:

The Smitsen DS-9C is an excellent Crepe tape machine

The DS-9C is excellent for applying crepe tape. Every DS-9C comes standard with the knife that cuts through the Crepe tape and the thread at the same time. The machine can extended with a Crepe tape binder or the CM4900-3 Crepe Tape infeeder.

Features on DS-9 series sewing head:

- Upper and Lower oil bath (all models)

- Variable pulley preinstalled (all models)

- Air operated pneumatic knife (DS-9C, DS-9CW)

- Continues rotating shear knife (DS-9A, DS-9AW)

- Smitsen DS-9A:

Ideal for hand operated installations with a simple electrical technical setup. Ideal for working with a foot pedal

- Smitsen DS-9A.1 (submodel): Every DS-9A can be converted to a Single thread machine and vice versa by changing some parts and resetting up the machine according to instructions. Ordering from the factory as a pre-installed single thread machine is also possible by referring to model name DS-9A.1

- Smitsen DS-9AW: Same features as the DS-9A but with 2 needles and 4 threads.

- Smitsen DS-9C:

The most popular of the series. it has an integrated knife that cuts through thread and crepe tape.

- Smitsen DS-9C.1 (submodel): Every DS-9C can be converted to a Single thread machine and vice versa by changing some parts and resetting up the machine. Ordering from the factory as a preinstalled single thread machine is also possible by referring to model name DS-9C.1

- Smitsen DS-9CW: Same features as the DS-9C but with 2 needles and 4 threads.

- Smitsen DS-9P:

Originally created for the potato but also a great choice when using an external knife. from your installation.

- Smitsen DS-9P.1 (submodel): Every DS-9P can be converted to a Single thread machine and vice versa by changing some parts. Ordering from the factory as a preinstalled single thread machine is also possible by referring to DS-9P.1

FAQ on Smitsen DS-9 series models.

- Can parts of the Smitsen DS-9 series be exchanged with Newlong? The Smitsen parts for DS-9 series are 100% compatible and exchangable with the same machine models from Newlong

- What oils can i use to fill up the upper and the lower oil bath? We advice Shell Tellus #32 or simular oils to fill up the oil bath. Are you working with food products? We advice a food grade oil such as Fuchs Cassida HF32

- How much oil goes into the oil bath? The upper oil bath uses 1600CC of oil. The lower oil bath uses 160cc of oil.

- After how many hours do i have to renew the oil? When a machine is new you have to renew the oil after 1000 hours of operation. After this oil should be renewed after 2000 hours of operation.

More technical question? go to our our technical section.

Why servicing your machine is so important?

Bag sewing machines are made up of hundreds of moving parts. All the parts must move in synchronization with each other. All the parts need to be properly lubricated to keep it sewing. As recommended by the manufacturer, your machine must be serviced regularly. Failure of service and repair can eventually lead to premature wear of parts, misalignment of parts or failure of parts in the machine.

Improper stitch formation thread breaking, and needles breaking are signals that you need to get the machine in for service immediately.

A bent needle and incorrect threading can cause problems. If your machine is well maintained and serviced but doesn’t seem to stitch properly, try replacing the needle first and re thread the machine according the threading signal